When the swingarm bearings need replacing in your dirt bike or ATV you'll know by the loose or unstable feeling of movement, or what is also known as chatter, in the rear of the bike.

Of course, it never seems easy pinpointing problems on dirt bikes or ATVs and this case is no different because the rear chatter while riding could also mean bad linkage (see below) or shock bearings. It all feels mostly the same.

Therefore, if you feel this chatter, pop your dirt bike on a stand and have someone push and pull (shake) the rear tire while you watch for noticeable slop in any of those areas. Any side-to-side or up-and-down play or what is also known as slop, is indicative of bad bearings. Pushing and pulling on the tire to check for swingarm issues should be a part of your regular maintenance check anyway.

On an ATV lift the quad off the ground by the frame using a jack or stand and have someone pull the swingarm back and forth to determine if it's the swingarm or rear axle.

Now, once you've determined the swingarm as the problem and since this is a "how to" on swingarm bearings, you'll need to replace them.

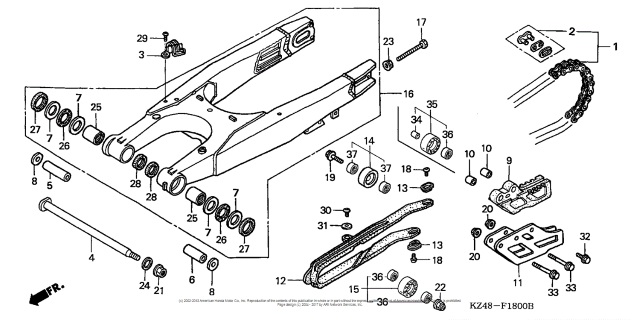

A standard diagram of the swingarm: Seal (#27), Thrust Washer (#7), Thrust Bearing (#26), Second Thrust Washer (#7), Needle Bearing (#25), and Seal (#28)

Unlike wheel bearings, swingarm bearings look more like embedded needles than small little balls. At least configurationally. Also, they do not come sealed. A rubber seal exists but over time or with excessive power washing, moisture finds its way inside and corrupts the bearings. Once water gets inside, it's trapped, then breaks down the needles that make the bearings and your bike chatters. Especially on cold winter days. OK, that part is not true.

Swingarm Bearing Maintenance

A thorough job at proper maintenance to the swingarm bearings means removing the swingarm. You're right - it's not a fun job. But this process allows you to remove the bearing seals to clean and grease the bearings. Additionally, you can identify any breakdown of the seals and get them replaced before things go south.

If you'd rather not remove the swingarm then at the very least remove the swingarm bolt, clean and grease it. The bearings on most dirt bikes and ATVs ride on the bolt so the grease applied eventually spreads to the bearings. This little bit of maintenance helps prolong the life of the bearings.

Mechanic's Tip: If you find swingarm slop, try greasing the bolt before anything else and see if this solves the problem. Sometimes a little grease goes a long way...

One thing to keep in mind is your bike's bearing set-up might include a thrust washer and thrust bearing behind the seal. This bearing doesn't benefit from the grease applied to the swingarm bolt and is often the first to break down. If that's the case, replace all the bearings.

How to Install Swingarm Bearings

Before installing new swingarm bearings you must remove the old ones. A bearing removal tool works best like this Motion Pro or this BikeMaster. The cheap and dirty method involves using a socket slightly larger on one side and a slightly smaller socket on the other side along with a vice or a press. Remove the seals with a flathead screwdriver, or similar. Then remove the thrust washers and bearings if equipped. Finally, remove the swingarm bearings.

Mechanic's Tip: Well-maintained swingarm bearings often remove without the need for a removal tool. But more often than not they've rusted in place.

As for install, use a bearing install tool like this Motion Pro. You can also employ a cheap and dirty method here as well which involves a bolt and washers approximately the same size as the swingarm bearings and use those as a press. Don't even think about using a hammer. Or a mallet. Press them in. Hammering leads to damaged bearings which results in the bolt seizing into the bearings and you're looking at a 10 on the removal difficulty scale.

Pack the bearings with grease, and using your installation tool, press or pull (depending on your preferred method) the bearings into place - keep it straight. The process is a bit tedious but should prove easy. Any necessary force means you're installing them wrong - likely at an angle. Similar to hammering, this results in the bolt seizing into the bearings.

Add the thrust washer and bearing thrust, if applicable, then the seal.

Use OEM or aftermarket swingarm bearings like this All Balls Kit or this Pivot Works Kit as replacements.

How To Replace Linkage Bearings

What, there's more? Yes. If you're replacing the swingarm bearings it's a really good idea to replace the linkage bearings and vice versa. You have to take the linkage apart to the remove the swingarm so think of it like killing two birds with one stone.

A standard diagram of the cushion arm (linkage): Needle Bearings (#21 & #22)

The removal/install process is exactly the same for the linkage bearings as the swingarm bearings. The bearings even resemble each other. This Motion Pro tool removes swingarm and linkage bearings.

Use OEM or aftermarket linkage bearings as replacements.

Once packed, get out and ride. Swingarm and linkage bearings last for years...if you properly maintain them.

For more on bearings, read How To Replace Wheel Bearings On Your Dirt Bike.