If you're in the market for a new set of brake pads it should come as no surprise that you have some choices.

And we're not talking brands.

A variety of brake pads exist and they don't all fit one application. By variety we mean what compound goes into creating the pad. You can dive into the deep end and study all the different types of brake pads because manufactures love to incorporate various combinations of materials but to keep it easy, we'll boil it down to four primary base compounds:

- Organic

- Sintered

- Kevlar

- Semi-Metallic

Each style of brake pad offers pros and cons based on the riding conditions and style of riding. Plus, you'll soon learn that other descriptions often take place of the commonly held one. We'll help decipher each one and let you decide what's best for your dirt bike.

Organic Brake Pads

Organic brake pads are also known as carbon brake pads. You'll also see them identified as NAO or non-asbestos organic. Yes, you read right. That cancer causing stuff formerly widely used as home insulation also helped stop cars. But no longer! Organic pads use Aramid fibers (yet another identifier) which are synthetic and quite strong.

Organic pads work great in racing conditions but not so great when it's wet. These pads perform very well in dry conditions and the price point is competitive. But even on dry days, tracks usually get watered down thus elevating the moisture content which hinders the performance of organic pads. Most dirt bike riders look elsewhere but off-roaders especially desert riders like them. Check out EBC X Series Carbon Brake Pads.

Sintered Brake Pads

What the heck is sintered? Don't ask, don't tell. We have no idea. Sounds like the name of a cool band. Actually it's a process that presses together various metallic compounds like copper. That's all were going to give you because it's a bit more complex than that and all you really need to know is this is a great brake pad for all conditions.

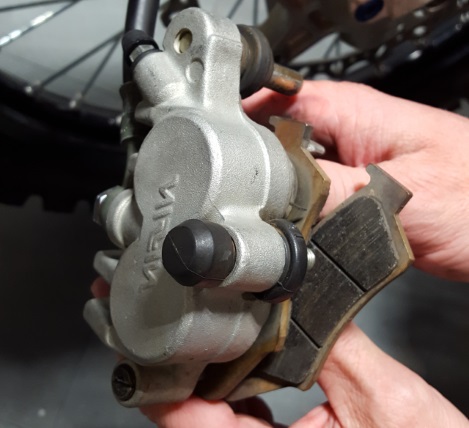

Sintered brake pads

Sintered brake pads fight heat buildup, last long, don't beat on your rotors and provide excellent response. The sintered type is generally more expensive but longevity helps equal the cost out from other less expensive materials. If you're looking for new brake pads, consider sintered, especially when racing. Check out Driven Sintered Brake Pads or EBC HH Brake Pads.

Kevlar Brake Pads

The same stuff that blocks a bullet also helps stop your dirt bike. Kevlar is not widely used in dirt bike applications as it's more common amongst the street bike crowd. It is a top-of-the-line pad - so is the cost - wear much slower than other pads, get along well with rotors and provides serious braking bite.

However, like the organic pads, their use is limited so it's best to look elsewhere for brake pads that standup in varying conditions. But for off-roaders and enduro not competing in wet conditions consider Galfer Kevlar Compound Brake Pads.

Semi-Metallic Brake Pads

The most common and widely used pad with the weekend warrior and trail riders is the semi-metallic brake pad. (There's a band name in there somewhere!) It's a versatile and affordable brake pad. It's also the harshest on rotors and wear quicker than sintered but most manufacturers have figured out how to reduce these negatives with today's technology. You can't go wrong with a semi-metallic pad and it offers a great option for the budget conscious. Check out Galfer Semi-Metallic Brake Pads.

Semi-Metallic brake pads

Ceramic Brake Pads

Ceramic is another common material used in brake pads but it's not very popular for use on dirt bikes. You'll also find ceramic mixed in with any of the above, usually the organic pads, but it poses the same limitations in wet conditions.

Code Ratings

Whatever type of brake pad you decide it's worth noting the two digit coding system from E to H. This "Brake Edge Code" is for cars and street motorcycles but many pads crossover for dirt bike uses thus include this coding system that's mandated by the Department of Transportation for street use.

When displayed you'll see EE or HH, etc. The first letter indicates how much "fade" or friction at lower temps (e.g. 250 F) and the 2nd letter indicates the fade at higher temps (e.g. 600 F). The higher the letter the better the pad holds up under hot and cold conditions.

Related Articles include: